What are patio blind brackets made of - PP or HDPE polypropylene

PP or HDPE polypropylene? A quick guide for patio blind contractors.

PP or HDPE? Before we explain which plastic to choose and why brackets for movable terrace blinds (commonly known as "movable boards"), you first need to understand how the two materials differ and what they have in common.

What is the difference between polypropylene and HDPE? Much depends on the density

As always - the devil is in the detail. See the 5 key differences that are important when comparing polypropylene and HDPE handles:

Price of material

HDPE grips should be cheaper than those made from polypropylene. Especially as some grip manufacturers use recycled HDPE. (ATTENTION! remember to compare the price of the bracket, you must take into account the number of sockets and the area you can cover with one set)

Mechanical properties HDPE and polypropylene blinds

Polypropylene is denser, stiffer and more durable than HDPE. It stands up better to prolonged use and high temperatures. Is this a significant difference worth the price? You'll find out best by taking a grip of these different materials. Those made of polypropylene are 'stronger'. They are harder to bend. Even harder to break. There is a reason why you need a hacksaw to cut them.

Workmanship

When comparing handles made from polypropylene with those made from recycled HDPE (i.e. HDPE regranulate), the difference is even more pronounced. Despite its many positive features (lower production cost, lower consumption of raw materials) recycled" plastic does not stand up for itself in terms of quality. Not surprisingly, The recycled material may have greater variations in chemical composition and viscosity, which affects casting precision. For handles requiring a close fit (e.g. rotary mechanisms), this can be a problem.

Risk of damage

After several recycling cycles, HDPE can be more brittle or less flexible. In moving parts, this means faster wear or a risk of breakage. Residues of other plastics or additives (e.g. dyes, metals) may be present in the recyclate, which worsen durability or cause dimensional instability.

Questionable aesthetics

Finally, there is one more disadvantage that is important for the end customer whose terrace, balcony or gazebo you will be enclosing: HDPE often has less uniform in colour, is more matt, may have roughness or visible inclusions.

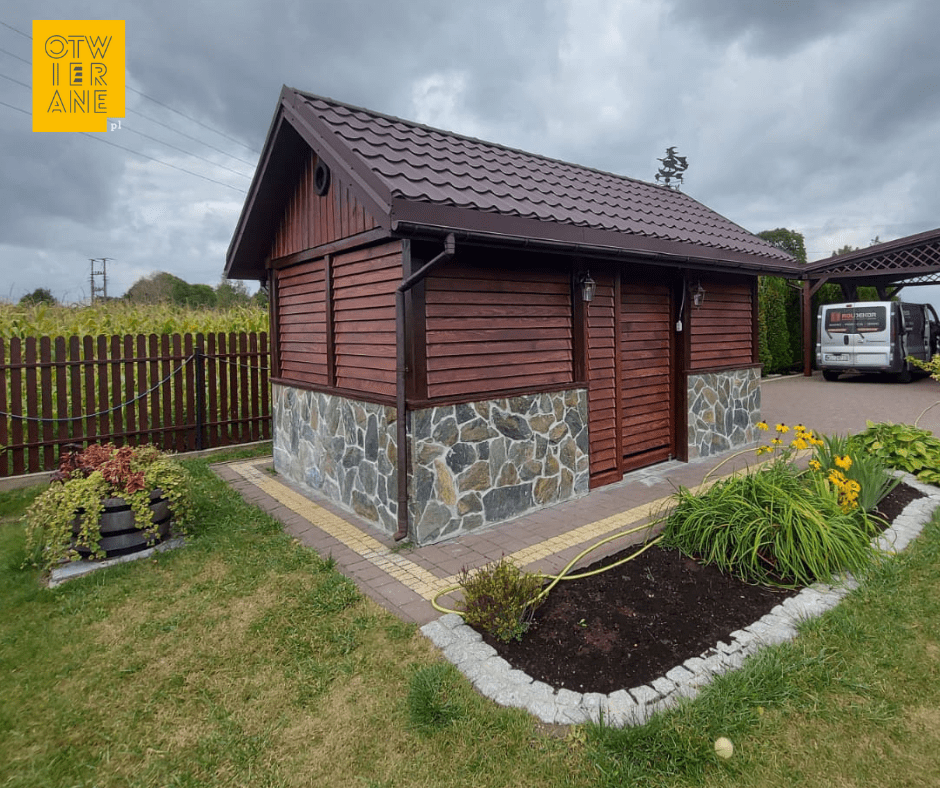

This is why we at Otwrane.co.uk only offer handles OpenUp system made of refined polypropylene. We tested their durability, and thus their reliability, in an ageing chamber.

Polyolefins, or what polypropylene and HDPE have in common

Polyolefins is a group of plastics (polymers) formed from simple chemical compounds called olefins - mainly ethylene i propylene. The most popular polyolefins are:

- PE (polyethylene) - including HDPE (high density),

- PP (polypropylene).

These are thermoplasticsThey are heat mouldable. They have very good mechanical properties and are resistant to external conditions. They can withstand large temperature differences. They are not susceptible to pests. They do not absorb water, do not rot, do not corrode and are UV-resistant, which makes them ideal for outdoor applications such as terraces.

Both HDPE and PP are significantly lighter than metalwhich makes installation easier and reduces the load on the structure (e.g. pergola). They do not need to be painted, protected or maintained. They do not react with wood, aluminium or steel screws. They do not cause discolouration or galvanic corrosion.

This makes them one of the most widely used plastics in the world. They are used to manufacture thousands of different products everyday and technical items, from food containers, bottles, packaging to sewage pipes or toys. And handles for movable patio blinds.

Polypropylene PP or HDPE - why the material is important

Deforming and breaking joints, imprecisely made components, increase costs. Installation can take longer and require more brackets with which to replace the defective ones. Added to this is the risk of complaints from customers who mishandle vulnerable blinds.

As a result, more and more customers choose polypropylene every year. brackets for movable terrace blinds OpenUp system. If you are a contractor, join them - register on our sales platform: OFFER FOR COMPANIES